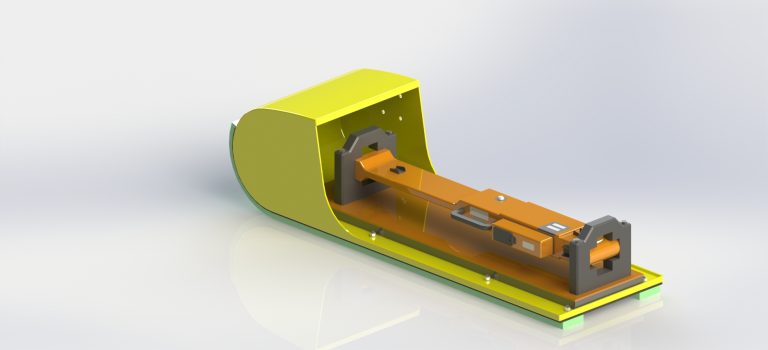

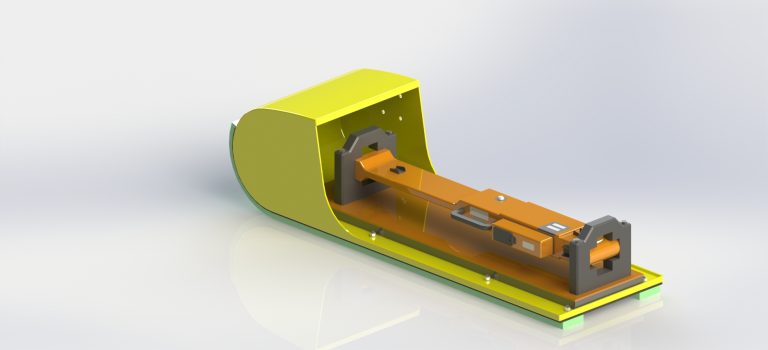

Sled Render

Latest Projects Sled Render Reverse engineered a legacy metal detector sled to produce new manufacture drawings.

Expert level 3D Modelling using Solidworks. Sheet Metal,

Weldments, Configurations, Surface modelling, 3D sketches, FEA, Mate Controller Animations. All drawings done to BS8888 with GD&T when required.

Don’t let your 3D design dreams go to waste. Let’s turn them into a reality!

We have extensive design and production engineering experience in the Space, Automotive/Motorsport, Optics, Oil & Gas, Energy and Special Projects industries, and we are confident that we can resolve your engineering issues or point you in the right direction.

We aim to establish professional, long lasting relationships with all customers and suppliers.

Please contact us for a free quote.

Expert level 3D Modelling using Solidworks. Sheet Metal, Weldments, Configurations, Surface modelling, 3D sketches, FEA, Mate Controller Animations. All drawings done to BS8888 with GD&T when required.

We have years of Production Engineering experience in the Automotive sector, so you can be assured that your product will be designed to be manufacturable and cost effective, whilst meeting your strength and weight specifications. Accuracy will be maintained using the most up to date manufacturing processes available.

An initial email, followed by a Teams video call or in person meeting if necessary to estimate work needed and cost

A series of meetings to ensure the customer is happy with the progress of the design

Transfer of the files in the desired format

Result is a happy customer that will return next time they require support!

Latest Projects Sled Render Reverse engineered a legacy metal detector sled to produce new manufacture drawings.

Latest Projects Cyclist Wind Tunnel Designed a variety of components of a revolutionary cyclist wind tunnel, ranging from the large conical end diffuser to the

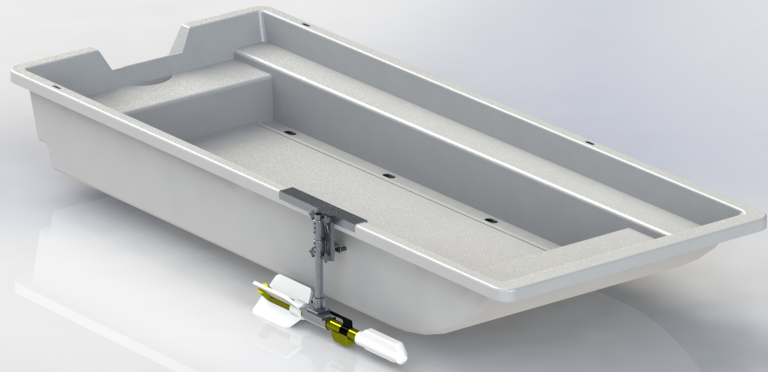

Latest Projects Boat Design Reverse engineered a fibre glass boat to aid the design of mounting equipment for a metal detector.

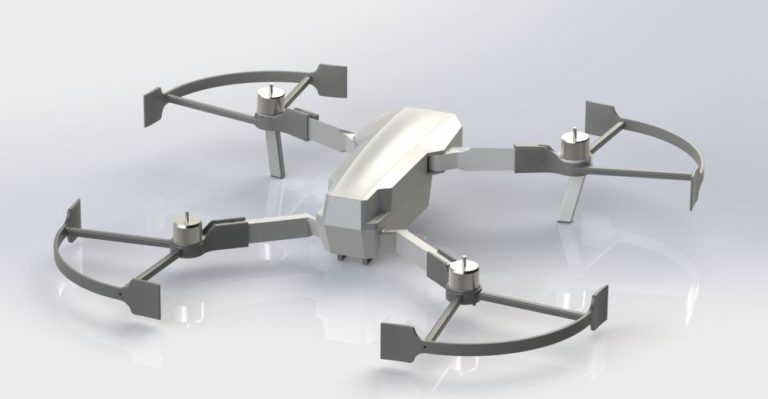

Latest Projects Drone Render Reverse engineered a Mavic Pro drone with a 3D scanner and Vernier calliper to aid the design of some propeller guards.

Lorem ipsum dolor sit amet, consectetuer adipiscing elit, sed diam nonummy nibh euismod tincidunt ut laoreet dolore magna aliquam erat volutpat. Ut wisi enim ad minim veniam, quis nostrud exerci tation

Lorem ipsum dolor sit amet, consectetuer adipiscing elit, sed diam nonummy nibh euismod tincidunt ut laoreet dolore magna aliquam erat volutpat. Ut wisi enim ad minim veniam, quis nostrud exerci tation

4 Russell Chase, Binfield,

Bracknell, RG42 4FZ

Mobile Number: +44 (0) 7762 608614

Keep up to date with our latest projects on our facebook & instagram page, or reach out directly to us via whatsapp!